Ψεκαστήρες σκανδάλης, Όσον αφορά την αρχή λειτουργίας τους, είναι ένας τύπος ψεκαστήρα αντλίας. Χρησιμοποιούνται ευρέως σε μια ποικιλία βιομηχανιών, συμπεριλαμβανομένων των οικιακών χημικών ουσιών, προϊόντα φροντίδας αυτοκινήτων, προμήθειες κατοικίδιων ζώων, και προϊόντα κηπουρικής.

Ένα σύντομο ιστορικό ψεκαστήρων χειρός

Η ιστορία των ψεκαστήρων Trigger είναι μια ιστορία μιας απλής ιδέας που εξελίσσεται για να γίνει ένα απαραίτητο εργαλείο στη σύγχρονη ζωή. Η βασική αρχή της μετατροπής του υγρού σε μια λεπτή ομίχλη ή ρεύμα ήταν εδώ και αιώνες, Αλλά ο σύγχρονος ψεκαστήρας χειρός είναι προϊόν της πλαστικής τεχνολογίας μετά τον Β 'Παγκόσμιο Πόλεμο.

Πρώιμες μέρες: Ο λαμπτήρας συμπίεσης

Πριν από τη δεκαετία του 1960, Οι πρόωροι ψεκαστήρες χρησιμοποίησαν μηχανισμό συμπίεσης-βολού. Όταν ο χρήστης συμπιέζει έναν λάμπα από καουτσούκ, θα αναγκάσει τον αέρα στο μπουκάλι, Σφίγγοντας το υγρό μέσα από ένα ακροφύσιο. Αυτά ήταν συχνά δυσκίνητα και δεν ήταν πολύ αποτελεσματικά για επαναλαμβανόμενη χρήση.

Η αυγή των πλαστικών

Η ταχεία πρόοδος των πλαστικών μετά τον Β 'Παγκόσμιο Πόλεμο επανάσταση στη συσκευασία. Τα πλαστικά ήταν φθηνότερα, πιο ανθεκτικός, και θα μπορούσε να διαμορφωθεί σε σύνθετα μέρη, Κάνοντας δυνατή την αυτοματοποίηση του συγκροτήματος ψεκαστήρα. Η εταιρεία Drackett, Κατασκευαστής γυαλιού Windex, ήταν ένας βασικός καινοτόμος στην προώθηση της χρήσης αυτών των νέων πλαστικών ψεκαστήρων.

Η επανάσταση του τύπου σκανδάλης

Τα τέλη της δεκαετίας του 1960 είδε την εισαγωγή του ψεκαστήρα τύπου σκανδάλης. Αυτός ο σχεδιασμός ήταν ένα σημαντικό άλμα προς τα εμπρός, επειδή ήταν πολύ πιο εργονομικό και λιγότερο κουραστικό για το χρήστη από τα παλιά μοντέλα Squeeze-Bulb. Τραβώντας ένα μοχλό, Μια μικρή αντλία μέσα στον ψεκαστήρα θα τραβούσε υγρό από τη φιάλη και θα την εξαναγκάσει από το ακροφύσιο.

Σύγχρονες εξελίξεις

Οι σημερινοί ψεκαστήρες χειρός συνεχίζουν να εξελίσσονται. Τώρα διαθέτουν ρυθμιζόμενα ακροφύσια για εναλλαγή ανάμεσα σε μια λεπτή ομίχλη και ένα ισχυρό ρεύμα, και χρησιμοποιούνται σε μια τεράστια ποικιλία προϊόντων, από οικιακά καθαριστικά και ψεκασμούς κήπου μέχρι φροντίδα αυτοκινήτων και προμήθειες κατοικίδιων ζώων. Το απλό τους, αποτελεσματικός, και ο φιλικός προς το χρήστη ο σχεδιασμός τους έχει κάνει ένα μόνιμο προσάρτημα σε νοικοκυριά και βιομηχανίες παγκοσμίως.

Τύποι ψεκαστήρων χειρός

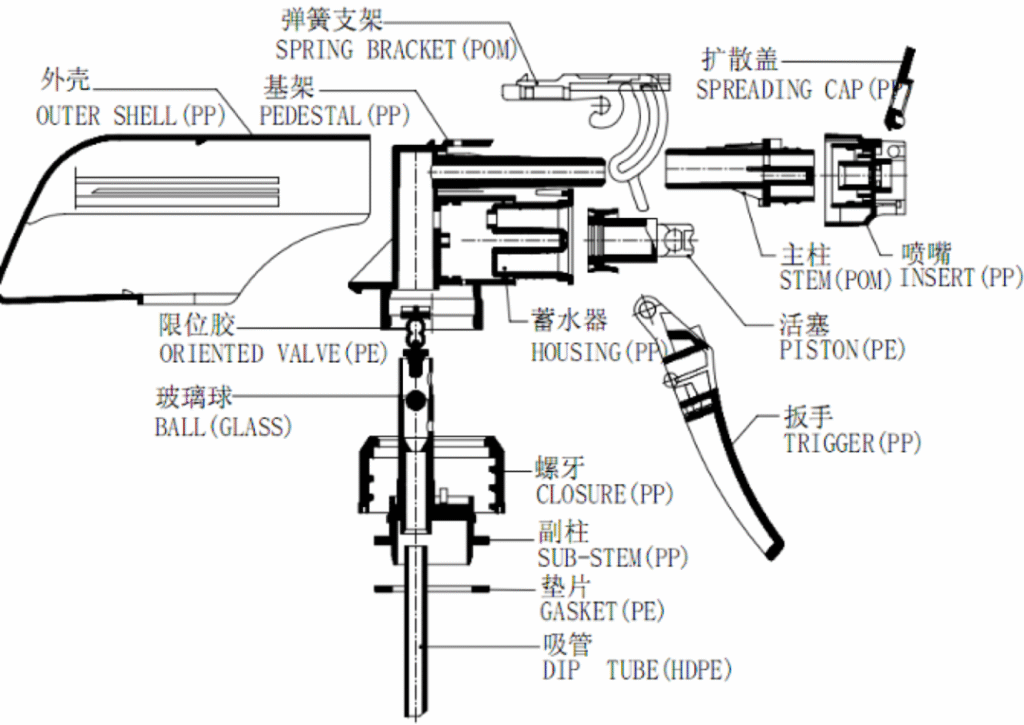

Οι ψεκαστήρες ενεργοποίησης συνήθως ταξινομούνται με δύο κύριους τρόπους: από την εσωτερική δομή της αντλίας τους και από τον εξωτερικό τους σχεδιασμό.

Ταξινόμηση με εσωτερική δομή

- Κατακόρυφη αντλία: Αυτός είναι ο πιο συνηθισμένος και οικονομικός τύπος. Η αντλία είναι τοποθετημένη όρθια και συχνά κρύβεται μέσα στο σώμα του ψεκαστήρα.

- Οριζόντια αντλία: Η αντλία τοποθετείται σε γωνία 45 μοιρών. Αυτός ο σχεδιασμός μπορεί να επιτρέψει μεγαλύτερη διαδρομή αντλίας και μεγαλύτερη έξοδο. Ορισμένα μοντέλα οριζόντιας αντλίας έχουν επίσης σχεδιαστεί για να είναι αντι-τερματισμό, ακόμη και όταν το ακροφύσιο είναι στο “επί” θέση.

- Ολικός: Αυτός ο τύπος δεν περιέχει μεταλλικά μέρη, καθιστώντας το ιδανικό για προϊόντα που μπορεί να αντιδρούν ή να διαβρώνουν μεταλλικά εξαρτήματα, όπως η άνοιξη.

Ταξινόμηση με εξωτερικό σχεδιασμό

- Ψεκαστήρες: Αυτοί οι ψεκαστήρες έχουν κλειστό σχέδιο που καλύπτει τον μηχανισμό εσωτερικής αντλίας. Είναι συχνά κατασκευασμένα για να είναι παραβιάσεις ή να αποφεύγουν διαρροές κατά τη μεταφορά, δοσολογία 0.9cc-1.5cc, Συνήθως χρησιμοποιούνται σε οικιακά προϊόντα καθαρισμού, προϊόντα φροντίδας αυτοκινήτων κ.λπ..

- Μη ψεκαστήρες: Αυτός ο τύπος έχει πιο ορατό, εκτεθειμένη δομή αντλίας, Συνήθως ονομάζεται ψεκαστήρας μίνι σκανδάλης. Βρίσκονται συχνά σε προϊόντα όπου είναι επιθυμητή μια κομψή ή απλή εμφάνιση, όπως στη βιομηχανία κομμωτηρίων, προϊόντα αρωμάτων στο σπίτι κ.λπ..

Το Ruispack παρέχει διαφορετικά είδη ψεκαστήρων σκανδάλης που για διαφορετικό σκοπό, Βρείτε αυτό που θέλετε στον παρακάτω σύνδεσμο https://www.ruispack.com/product-category/dispensers-closures/trigger-sprayers/