Raw material & melting process:

The main material of glass are quartz sand, soda ash, and limestone, these materials need to undergo crushing, de-ironing, and drying to ensure uniform particles and less than 0.1% impurities.

And then all these raw materials need to be mixed, and fed into a furnace, melting at a high temperature of 1500-1600°C into liquid glass. the furnace needs to be constantly stirred to remove air bubbles and ensure a uniform composition.

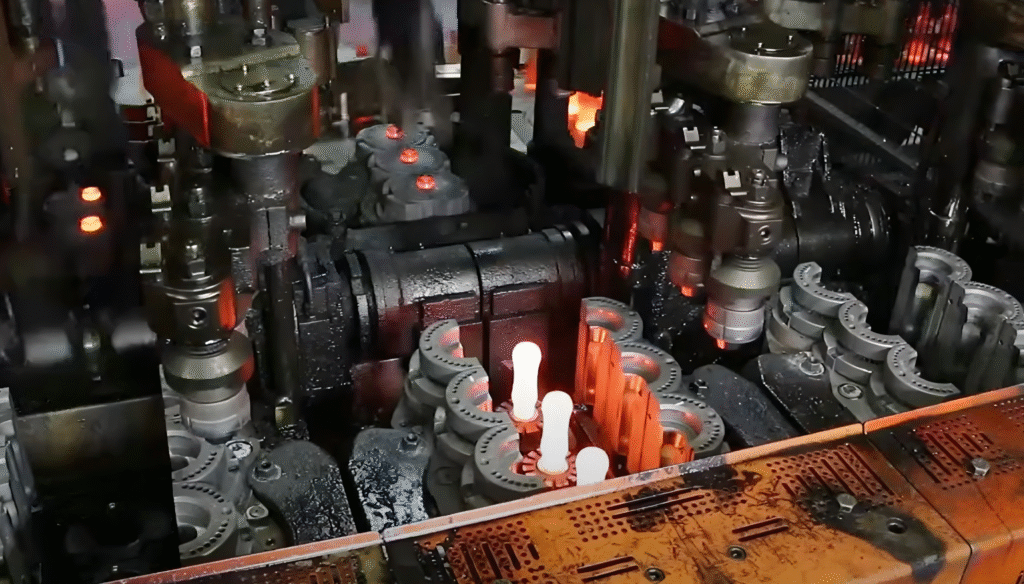

Shaping techniques:

There are 2 methods to make glass bottles: blow molding and press molding.

Press molding method is efficient for simple containers like food jars etc.

Blow molding method are usually for complex designs like perfume bottles.

The spray bottle/lotion bottles we used for cosmetics are all made by blow molding method. Molten glass is cut into droplets, inflated in molds to create different shapes.

Annealing :

The formed glass bottles need to be treated in an annealing oven for 4-6 hours according to a specific temperature curve, such as slow cooling from 550°C to room temperature, to eliminate internal stress and avoid breakage due to temperature difference during subsequent use.

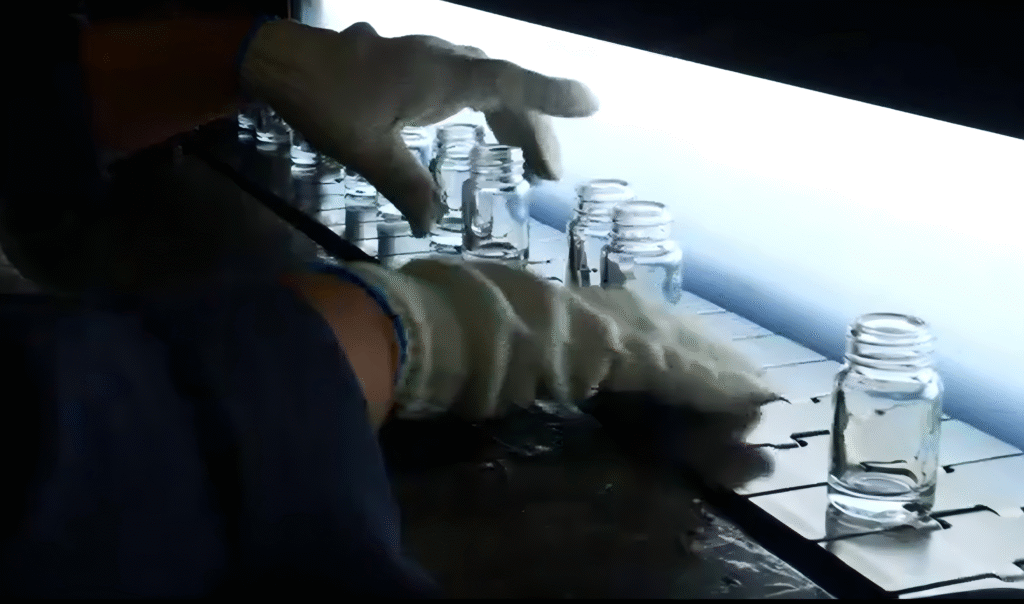

Quality check & packing:

After the glass bottles cool to room temperature, workers will visually inspect under strong light and measure the size of the bottles to screen out defective products.

Qualified bottles will be packed well in cartons and pallets to make sure safe transit.

Contact us to get more inspirations for your skin care glass packaging.