Laminerte kosmetiske barriererør er vanlige hverdagslige emballasjeløsninger, mye brukt for produkter som tannkrem, kosmetikk, og mat.

Produksjonsprosessen for laminerte rør

03. Skjæring

This step involves longitudinally cutting the wide rolls of composite laminate sheet into narrower rolls of the precise width required for subsequent printing and tube-making processes.

04. Printing

Laminate sheets employ flat surface printing. The main printing technologies used include letterpress, flexographic, and gravure (rotogravure) printing. Additional processes, such as silk screen printing and hot stamping (foil), are often used to enhance the tube’s decorative effect, making the print more exquisite and engaging.

A small volume of reverse-printed laminate sheets has also appeared in the market, primarily utilizing gravure printing. The production process for this type of laminate differs slightly: after the film is blown, the printing (reverse printing) is done first, followed by the lamination step.

05. Tube Making

Tube making is the final manufacturing stage for the laminated tube. It primarily consists of three sub-steps:

EN. Body Seaming (Welding): The pre-produced composite laminate is welded to form the tube body. High-frequency (HF) welding is the main technique used. The two longitudinal edges of the laminate are typically lap-welded to form the tube, resulting in a visible longitudinal seam.

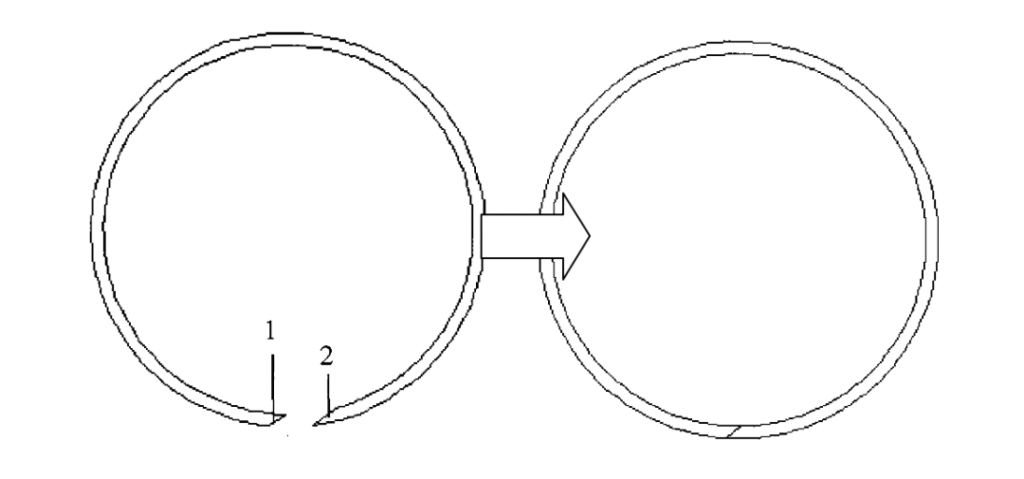

As tube-making technology advances, the production of invisible-seam laminated tubes is increasing. In the main process for invisible seams, the two edges of the laminate sheet are skived (taper-cut at an angle) before rolling, then abutted (with complementary angles) and finally hot-welded. Since the thickness of this butt seam is close to the rest of the tube body, it does not have the noticeable ridge of a lap seam, effectively “hiding” the weld.

Another common method for invisible seams involves butt-welding the two ends of the laminate and simultaneously using a transparent heat-sealing strip to reinforce the weld.

B. Shoulder Production (Molding): The second step in tube making is the production of the tube shoulder. Currently, two main manufacturing methods are common:

Compression Molding: Polyolefin granules (like HDPE) are fed into an extruder screw, melted under shear, and accurately metered into a mold cavity pre-set to the shape of the shoulder. This mold, containing the molten material, moves to the next stage where it is combined with the tube body fixed on a mandrel. The molten material is then compressed and cooled to form the final shoulder, including the orifice and external thread. The advantage of this process is that the shoulder and tube body fuse together, resulting in a stable bond strength and a seamless, natural appearance. The drawback is that compression and cooling take more time, impacting overall tube-making speed.

Pre-Fabricated Shoulder Welding: The shoulder is pre-molded using injection molding before the tube-making process. During tube making, it is directly heated and welded onto the tube body. This method eliminates the time needed for on-line molding and cooling, significantly increasing the tube-making speed. derimot, it may result in slightly less stable bond strength and a less integrated appearance than compression molding.

C. Capping: The final stage of tube making is capping.

Pre-fabricated caps are attached to the tube’s orifice using capping equipment, either by screwing down or by snap-fitting. At this point, the production of the laminated composite tube is complete.

Laminated cosmetic tubes are now widely used and have become the dominant packaging form for personal care products like toothpaste. In the cosmetics sector, they are used for products such as hand creams, facial cleansers, conditioners, face creams, hair dyes, depilatory creams, and gels. In the food industry, applications include various sauces and condensed milk products. In pharmaceuticals, they are used for hemorrhoid creams, burn ointments, and eye ointments. Usage in other categories, such as pigments and shoe polish, is also growing. Given the existing advantages of laminated tubes, coupled with continuous technological innovation and new product development, the outlook for their application remains extremely broad.